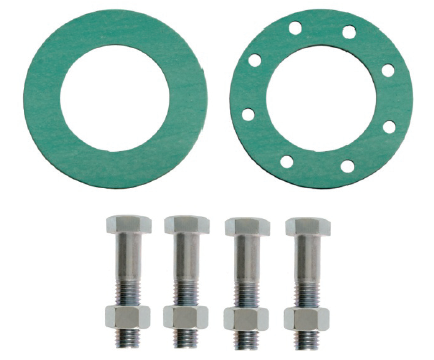

GFF - 150# Full Face Red Rubber Gasket

Downloads:

GFF - 150# Full Face Red Rubber Gasket

• 150# Full Face Red Rubber Gasket

• 1/8"

• Sizes 2" - 24"

Non-Asbestos

Red Rubber

Gasket: APG style CNA-750

- Constructed of aramid and other synthetic fibers and bonded with nitrile rubber (NBR).

- Max temperature rating: 750 degrees F

- (Continuous temp max: 460 degrees F)

- Max pressure limit: 1595 PSI

- (Continuous pressure max: 725 PSI)

- Suitable for: Water, air, and a variety of industrial gases and fluids; suitable for steam depending on operating conditions

- Meets ASTM F152

- Comparable products: Klinger C-4401, Garlock 3000

- Bolts: ASTM A307 Grade A zinc plated carbon steel

- Minimum tensile strength: 60,000 PSI

Nuts: ASTM A563 zinc plated carbon steel finished hex nut

- (There is another class of nut designated as “heavy hex” which is also used in industry. Our kits contain “finished hex” which is consistent with many other bolt & gasket set producers.)

Packaging:

- Box: Folding tab white mottled boxes

- Bolts are packaged in sealed poly bags

- Nuts are packaged in sealed poly bags

Gasket: APG style 0700

- Constructed of SBR (Styrene Butadiene Rubber)

- “Smooth” red rubber finish as opposed to rough “cloth” finish

- Max temperature rating: -20 to 170 degrees F, 210 degrees F intermittent

- Tensile Strength: 500 PSI

- Suitable for: hot & cold water, air, and neutral fluids

- Meets ASTM D-1330

Bolts: ASTM A307 Grade A zinc plated carbon steel

- Minimum tensile strength: 60,000 PSI

Nuts: ASTM A563 zinc plated carbon steel finished hex nut

- (There is another class of nut designated as “heavy hex” which is also used in industry. Our kits contain “finished hex” which is consistent with many other bolt & gasket set producers.)

Packaging:

- Box: Folding tab white mottled boxes

- Bolts are packaged in sealed poly bags

- Nuts are packaged in sealed poly bags

A.S.A Flanged Fittings

Class 125 Cast Iron Flanges and Fittings

Dimensions of Cast Iron Flanges, Bolts, and Ring Gaskets

| Nominal Pipe Size | Diam. of Flange | Thickness¹ of Flanges (Min.) | Diam. of Bolt Circle | Number² of Bolts | Diam. of Bolts | Diam.² of Bolt Holes | Length3,4 of Bolts | Size of Flat Ring Gasket | Size of Full Face Ring Gasket | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 6 | 5/8 | 4 3/4 | 4 | 5/8 | 3/4 | 2 1/4 | 2 x 4-1/8 | 2-3/8 x 6 | ||||||||||||||

| 2 1/2 | 7 | 11/16 | 5 1/2 | 4 | 5/8 | 3/4 | 3 | 2-1/2 x 4-7/8 | 2-7/8 x 7 | ||||||||||||||

| 3 | 7 1/2 | 3/4 | 6 | 4 | 5/8 | 3/4 | 3 | 3 x 5-3/8 | 3-1/2 x 7-1/2 | ||||||||||||||

| 3 1/2 | 8 1/2 | 13/16 | 7 | 8 | 5/8 | 3/4 | 3 | 3-1/2 x 6-3/8 | |||||||||||||||

| 4 | 9 | 15/16 | 7 1/2 | 8 | 5/8 | 3/4 | 3 | 4 x 6-7/8 | 4-1/2 x 9 | ||||||||||||||

| 5 | 10 | 15/16 | 8 1/2 | 8 | 3/4 | 7/8 | 3 | 5 x 7-3/4 | 5-9/16 x 10 | ||||||||||||||

| 6 | 11 | 1 | 9 1/2 | 8 | 3/4 | 7/8 | 3 1/2 | 6 x 8-3/4 | 6-5/8 x 11 | ||||||||||||||

| 8 | 13 1/2 | 1 1/3 | 11 3/4 | 8 | 3/4 | 7/8 | 3 1/2 | 8 x 11 | 5-5/8 x 13-1/2 | ||||||||||||||

| 10 | 16 | 1 3/16 | 14 1/4 | 12 | 7/8 | 1 | 4 | 10 x 13-3/8 | 10-3/4 x 16 | ||||||||||||||

| 12 | 19 | 1 1/4 | 17 | 12 | 7/8 | 1 | 4 | 12 x 16-1/8 | 12-3/4 x 19 | ||||||||||||||

| 14 OD | 21 | 1 3/8 | 18 3/4 | 12 | 1 | 1 1/8 | 4 1/2 | 14 x 17-3/4 | 14 x 21 | ||||||||||||||

| 16 OD | 23 1/2 | 1 7/16 | 21 1/4 | 16 | 1 | 1 1/8 | 4 1/2 | 16 x 20-1/4 | 16 x 23-1/2 | ||||||||||||||

| 18 OD | 25 | 1 9/16 | 22 3/4 | 16 | 1 1/8 | 1 1/4 | 5 | 18 x 21-5/8 | 18 x 25 | ||||||||||||||

| 20 OD | 27 1/2 | 1 11/16 | 25 | 20 | 1 1/8 | 1 1/4 | 5 | 20 x 23-7/8 | 20 x 27-1/2 | ||||||||||||||

| 24 OD | 32 | 1 7/8 | 29 1/2 | 20 | 1 1/4 | 1 3/8 | 5 1/2 | 24 x 28-1/4 | 24 x 32 | ||||||||||||||

A.S.A Flanged Fittings

Class 300 Cast Iron Flanges

Dimensions of Cast Iron Flanges, and Bolts

| Nominal Pipe Size | Diam. of Flange | Thickness of Flanges (Min.) | Diam. of Bolt Circle | Number of Bolts | Diam. of Bolts | Diam. of Bolt Holes | Length of Bolts | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 6 1/2 | 5/8 | 5.00 | 8 | 0.62 | 0.75 | 3 | ||||||||||||||||

| 2 1/2 | 7 1/2 | 3/4 | 5.88 | 8 | 0.75 | 0.88 | 3 1/4 | ||||||||||||||||

| 3 | 8 1/4 | 3/4 | 6.62 | 8 | 0.75 | 0.88 | 3 1/2 | ||||||||||||||||

| 3 1/2 | - | - | 7.25 | 8 | 0.75 | 0.88 | - | ||||||||||||||||

| 4 | 10 | 3/4 | 7.88 | 8 | 0.75 | 0.88 | 3 3/4 | ||||||||||||||||

| 5 | 11 | 3/4 | 9.25 | 8 | 0.75 | 0.88 | 4 | ||||||||||||||||

| 6 | 12 1/2 | 3/4 | 10.62 | 12 | 0.75 | 0.88 | 4 1/4 | ||||||||||||||||

| 8 | 15 | 7/8 | 13.00 | 12 | 0.88 | 1.00 | 4 3/4 | ||||||||||||||||

| 10 | 17 1/2 | - | 15.25 | 16 | 1.00 | 1.12 | - | ||||||||||||||||

| 12 | 20 1/2 | - | 17.75 | 16 | 1.12 | 1.25 | - | ||||||||||||||||

| 14 | 23 | - | 20.25 | 20 | 1.12 | 1.25 | - | ||||||||||||||||

| 16 | 25 1/2 | - | 22.50 | 20 | 1.25 | 1.38 | - | ||||||||||||||||

| 18 | 28 | - | 24.75 | 24 | 1.25 | 1.38 | - | ||||||||||||||||

| 20 | 30 1/2 | - | 27.00 | 24 | 1.25 | 1.38 | - | ||||||||||||||||

| 24 | 36 | - | 32.00 | 24 | 1.50 | 1.62 | - | ||||||||||||||||

Tightening Torque Values

| Nominal Dia (in) | Threads per inch | Clamp Load (Lbs) | ASTM A307 Grade A | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tightening Torque | |||||||||||||||

| K = 0.15 (Lubricated) | K = 0.17 (Plated) | K = 0.20 (Plain) | |||||||||||||

| 1/2" | 13 | 3831 | 24 | 27 | 32 | ||||||||||

| 5/8" | 11 | 6102 | 48 | 54 | 64 | ||||||||||

| 3/4" | 10 | 9030 | 85 | 96 | 113 | ||||||||||

| 7/8" | 9 | 12467 | 136 | 155 | 182 | ||||||||||